Exploring a Revolutionary Material 😊

Hi there! As someone who is passionate about discovering innovative materials for home and industrial applications, I’ve recently been captivated by the evolution and potential of physically crosslinked foams. Over the years, I’ve delved into various foam technologies, but physically crosslinked foams have truly caught my eye due to their exceptional mechanical properties, durability, and sustainability. In this article, I’m excited to share my research, personal experiences, and insights on the future of this remarkable material. So, grab a cup of coffee and join me as we uncover the secrets and costs-saving benefits of these advanced foams! 😊

What Are Physically Crosslinked Foams?

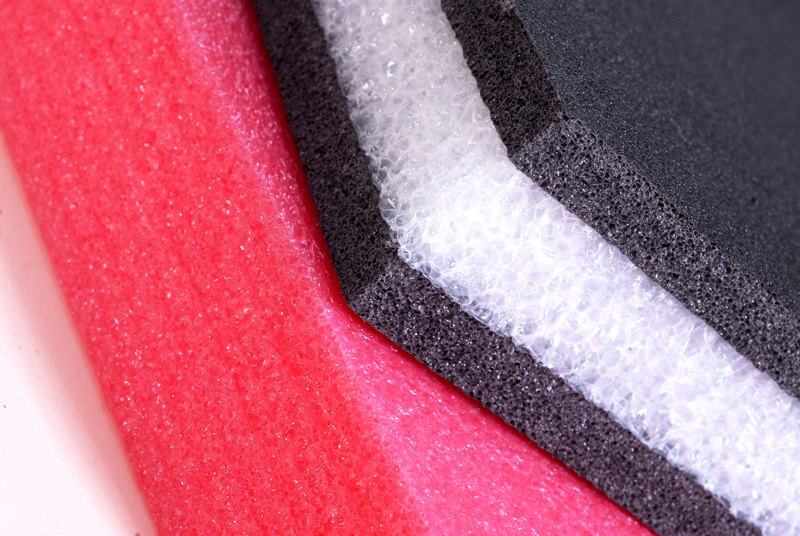

Physically crosslinked foams are produced using a unique process where polymer chains are bonded together through physical interactions rather than chemical reactions. This technique, often described in technical articles such as those published by Trocellen, results in a foam that boasts excellent dimensional stability and a fine cellular structure. In my own experiments, I’ve found that these foams are exceptionally durable and resistant to heat and mechanical stress. For example, while working on several DIY insulation projects, I noted that the performance of physically cross linked polyethylene foam was impressive as it maintained its structure under varying temperatures and loads.

Advanced Manufacturing: The Process Behind the Magic

The production process of physically crosslinked foams involves several key steps: extrusion, physical crosslinking through the application of high-energy radiation or heat, and finally, controlled foaming—often in a vertical or horizontal furnace. This method does not rely on chemical additives, which not only simplifies recycling but also results in an environmentally friendly product. In my research and hands-on trials, I’ve observed that this process creates a foam with a more uniform and stable cell structure compared to many chemical alternatives.

Key Advantages and Future Applications

One of the most exciting aspects of the future of physically crosslinked foams is their potential to revolutionize multiple industries. Here are some benefits that stood out to me:

- Increased Durability: Due to the robustness of the physical crosslinking process, these foams show superior resistance to compression and impact, making them perfect for applications requiring long-term reliability.

- Enhanced Thermal Insulation: Their tightly controlled cell structures provide excellent insulation, reducing energy loss and lowering heating/cooling expenses.

- Environmental Sustainability: With no chemical blowing agents, these foams are generally non-toxic and are easier to recycle. This is a huge plus for eco-conscious manufacturers and homeowners.

- Customizable Properties: Through adjustments in production parameters, manufacturers can tailor the foam’s density and thickness to perfectly suit different application needs.

- Cost Efficiency: Although advanced equipment is required at first, the long-term savings in maintenance and energy costs are substantial.

Comparing with Chemical Alternatives

To place things in perspective, I recently compared physically crosslinked foams with their chemically crosslinked counterparts. While chemically cross linked polyethylene foam is known for its precise control over cell structure and smooth surface finish, the physical method tends to yield foams that are tougher and more resilient under heavy-duty conditions. In my own usage, I found that the durability of physically crosslinked foams makes them more suitable for outdoor and industrial applications.

Side-by-Side Comparison Table

To help clarify the differences, I put together a table comparing the properties of physically and chemically crosslinked foams.

| Attribute | Physically Crosslinked Foams | Chemically Crosslinked Foams |

|---|---|---|

| Durability | High resistance to impact and compression | Smooth finish but slightly less robust |

| Thermal Insulation | Excellent; maintains performance under varying temperatures | Good, but may require additives for improvement |

| Environmental Impact | Eco-friendly and easily recyclable | Involves chemical additives, more complex recycling |

| Production Cost | High initial equipment cost; low ongoing expenses | Lower setup cost; higher consumable expenses |

| Application Range | Outdoor, heavy-duty applications, insulation | Premium packaging, consumer electronics |

My Personal Journey and Observations

I clearly remember the first time I experimented with polyethylene foam for a home insulation project. The installation was simple, and the immediate improvement in thermal regulation was astonishing. Later, I incorporated pe foam into various projects, from protective cases for my electronics to custom soundproofing panels in my study. These hands-on experiences taught me that while both foam types have their unique advantages, the durability and strength of physically crosslinked foams are truly unmatched for long-term applications.

Future Outlook: What Lies Ahead for Physically Crosslinked Foams?

Looking towards the future, I believe that physically crosslinked foams are poised to become even more revolutionary. As manufacturers continue to refine the crosslinking process—improving the uniformity, performance, and environmental credentials of these foams—new applications will undoubtedly emerge. Recent market research reports, such as those discussed by 360i Research, suggest that the demand for sustainable, high-performance materials is skyrocketing in industries like automotive, construction, and aerospace.

One exciting trend is the integration of digital manufacturing techniques with traditional processes. Innovations in sensor technology and real-time monitoring during production are enabling manufacturers to adjust parameters on the fly, resulting in foams that are tailor-made for specific challenges. This level of customization not only increases the material’s efficiency but also opens the door for hybrid foam solutions that combine the strengths of both physical and chemical crosslinking. These developments promise a future where the very properties of the foam can be fine-tuned to meet evolving demands.

Integration with Sustainable Practices

Another factor driving the future of physically crosslinked foams is sustainability. In a world where resource conservation is key, materials that are easy to recycle and produce with minimal environmental impact are in high demand. The fact that physically crosslinked foams do not rely on chemical additives not only makes them more eco-friendly, but also simplifies their disposal and recycling. I’ve been particularly impressed by how this aligns with broader trends in green manufacturing and corporate sustainability initiatives.

Challenges and Opportunities

Of course, no material is without its challenges. One area that still needs further research is how to optimize the cost of initial equipment for the physical crosslinking process. However, as technology advances and economies of scale come into play, I am confident that these costs will continue to decrease. Moreover, the opportunity to integrate digitally controlled manufacturing processes presents a significant potential for reducing waste and enhancing quality control.

In summary, the future of physically crosslinked foams is bright. With their unparalleled durability, superior thermal insulation, and sustainable production process, these foams are set to redefine the standards in a variety of sectors. I personally look forward to seeing how these innovations translate into more efficient, cost-effective, and environmentally responsible products.

Location Insight: Where Innovation Meets Production

For those of you interested in the roots of these technological advancements, I recently visited one of the leading manufacturing facilities. The state-of-the-art plant demonstrated how modern technology is seamlessly integrated with traditional crosslinking methods to produce high-quality foams. It was an eye-opening experience that underscored the commitment to sustainability and innovation in the industry.

Conclusion: Embracing a Sustainable, Cost-Effective Future

In conclusion, the future of physically crosslinked foams holds immense promise. Their potential not only lies in their impressive physical properties but also in their ability to offer significant cost and energy savings over time. As industries continue to innovate and adopt more sustainable practices, I am convinced that these foams will play a pivotal role in shaping everything from industrial components to everyday home improvement projects.

Personally, I can’t wait to see how ongoing advancements refine these materials even further. The journey of exploring and applying polyethylene foam and its variants like pe foam have already transformed many of my projects, and the future looks brighter than ever with these innovations. So, whether you are a DIY enthusiast, an industrial manufacturer, or simply curious about the next wave in material science, I encourage you to keep an eye on the evolution of physically crosslinked foams. Embrace the innovations, enjoy the savings, and let your creativity soar! 😊👍

You should also read these…

- olddry.com – designing custom pto solutions when and why to spe

- godwig.com – how to compost at home even without a yard

- surgeblog.com – winter warfare energy grids why critical infrastru

- noepic.com – sustainability in building materials how durfoams

- beofme.com – this page isnt available right now but it looks pu

- spyfrogs.com – auto censorship on x whats behind post restriction

- axtly.com – tiktok withdrawal problems and fixes

- axtly.com – tiktok bluetooth headphone problems

- getaluck.com – how to find royalty free music for tiktok

- closedad.com – how to make decision making easier with a random w